The cone is shaped from a carefully proportioned and uniformly mixed batch of ceramic materials so that when it is heated under stated conditions it will bend due to softening the tip of the cone becoming level with the base at a definitive temperature.

Pyrometric cone ceramics definition.

Once the appropriate cones are selected excellent reproducible results can be expected.

The ware inside both bisque and glaze firings are subject to quartz inversion as their temperatures reach 1063 f 573 c.

Temperature equivalents for orton pyrometric cones c cone numbers 022 14 these tables provide a guide for the selection of cones.

Ceramic foundation advises using a particular set of temperature equivalents for their cones which melt at 34 different temperatures each identified with its own cone number.

Please note that the cone chart gives 3 different temperatures for each cone number.

As discussed above the equivalent cone temperature depends upon how fast one gets to it.

Temperatures shown are for specific mounted height above base.

At this temperature quartz changes from the alpha to the beta state which means that the molecules rearrange themselves and expand 1 2 during heat up and contract the same amount during cooling.

Pyrometric cones have several practical uses in the ceramics studio.

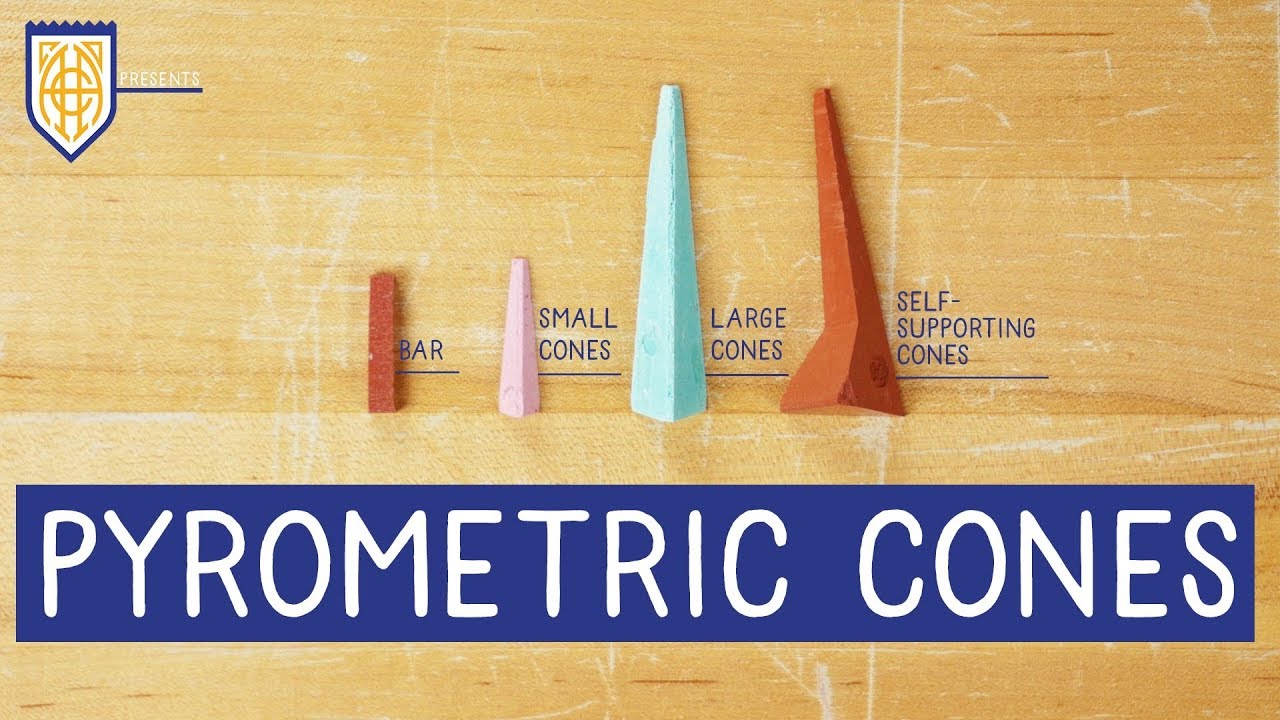

The pyrometric cone is a pyramid with a triangular base and of a defined shape and size.

Starting at 022 at the lowest temperature 1157 degrees f continuing to cone 01 then to cone 1 and to the hotest at cone 12 about 2420 degrees.

Pyrometric cones are used worldwide to monitor ceramic firings where consistent temperature is important to the quality of the final product being fired cones are used both in industry and by ceramic artists alike.

As firing measurement witness cones viewed through a kiln spy peep hole are the most accurate measure of a kiln s firing progress and for deciding when to shut down the kiln.

They are useful in determining when a firing is complete if the kiln provided enough heat if there was a temperature difference in the kiln or if a problem occured during the firing.

Look it up now.

Pyrometric cones measure heatwork the effect of time and temperature.

The actual bending temperature depends on firing conditions.

Pyrometric cones will be the first to let you know your ceramic firing is under control or that subtle changes.